Proof-load tested and FEA analysis completed at an independent facility. Download the detailed engineering report (USA, Canada, United Kingdom).

The Silva Cell is a product, but it is also a system. Each installation site has its own unique attributes – soil, tree species, hydrology, climate, and more – that influence how it is incorporated and how it will perform. From early on in the design phases, every component of the site should be considered thoughtfully within the context of this system

For engineers who want to begin using this system, visit our Getting Started section. Our team of technical experts is available to provide assistance throughout this process.

Information on the following is available by request. Please contact us for details.

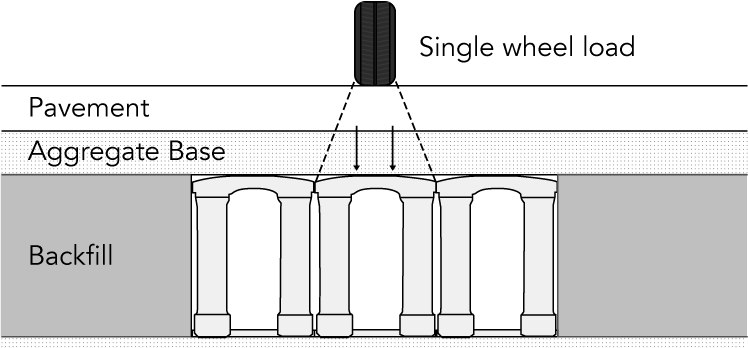

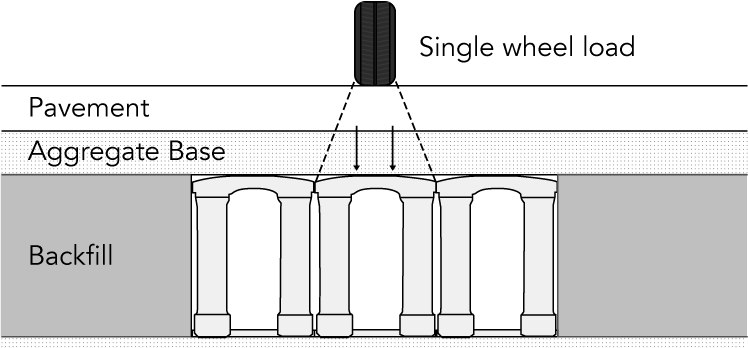

Independent lab testing and engineering analysis shows that Silva Cell 2, when installed per manufacturer’s specifications, meets or exceeds most loading requirements and safety factor, including AASHTO H/HS-20 (US), BS EN 1991-1-1:2002 (UK) and standards for tire contact surface area equal to 250 mm x 600 mm (Canada).

– 32,000 lbs maximum per axle

– 16,000 lbs maximum per wheel

– Tire contact area is 14.25″ radius

– 32,000 lbs maximum per axle

– 16,000 lbs maximum per wheel

– Tire contact area is 10″x 20″ rectangle

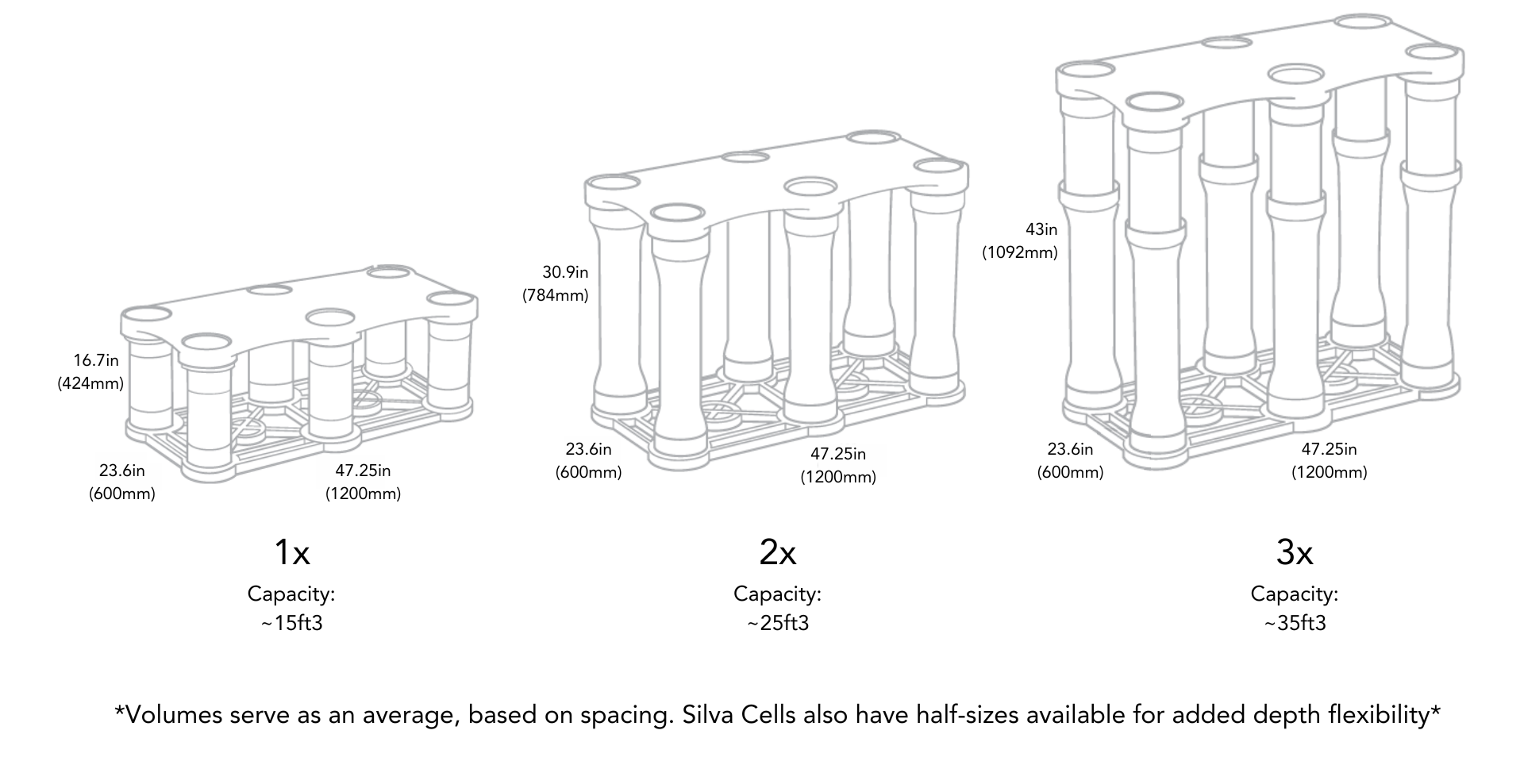

The table below provides the maximum load that can be on any single wheel (tire), or per axle, for a given pavement section, assuming tires have a contact area equal to either the AASHTO H-20 standard of a 14.25″ radius or the AASHTO HS-20 standard of a 10″x 20″ rectangle. For more details, please refer to the Silva Cell 2 Engineering Report and Testing Conclusions.

| Silva Cell System Type | Traffic Loading Standard | Pavers | |

| 3.15″ pavers 1″ sand base 12″ of aggregate |

|||

| Wheel | Axle | ||

| 1X | H-20 | 30,200 lbs | 60,400 lbs |

| HS-20 | 31,800 lbs | 63,600 lbs | |

| 2X | H-20 | 33,200 lbs | 66,400 lbs |

| HS-20 | 34,900 lbs | 69,800 lbs | |

| 3X | H-20 | 28,200 lbs | 56,400 lbs |

| HS-20 | 29,700 lbs | 59,400 lbs | |

| Silva Cell System Type | Traffic Loading Standard | Asphalt | |

| 4″ of asphalt 12″ of aggregate |

|||

| Wheel | Axle | ||

| 1X | H-20 | 40,600 lbs | 93,200 lbs |

| HS-20 | 48,700 lbs | 97,400 lbs | |

| 2X | H-20 | 51,200 lbs | 102,400 lbs |

| HS-20 | 53,500 lbs | 107,000 lbs | |

| 3X | H-20 | 43,500 lbs | 87,000 lbs |

| HS-20 | 45,500 lbs | 91,000 lbs | |

| Silva Cell System Type | Traffic Loading Standard | Concrete | |

| 4″ of asphalt 4″ of aggregate |

|||

| Wheel | Axle | ||

| 1X | H-20 | 34,900 lbs | 69,800 lbs |

| HS-20 | 35,900 lbs | 71,800 lbs | |

| 2X | H-20 | 38,300 lbs | 76,600 lbs |

| HS-20 | 39,500 lbs | 79,000 lbs | |

| 3X | H-20 | 32,600 lbs | 65,200 lbs |

| HS-20 | 33,600 lbs | 67,200 lbs | |

| Silva Cell System Type | Traffic Loading Standard | Pavers with Concrete | |

| 2.36″ pavers 5″ concrete |

|||

| Wheel | Axle | ||

| 1X | H-20 | 38,600 lbs | 77,200 lbs |

| HS-20 | 41,100 lbs | 82,200 lbs | |

| 2X | H-20 | 42,200 lbs | 84,800 lbs |

| HS-20 | 45,200 lbs | 90,400 lbs | |

| 3X | H-20 | 36,000 lbs | 72,000 lbs |

| HS-20 | 38,400 lbs | 76,800 lbs | |

Loading capacity can be adjusted based on section profile changes; the typical applications shown in the table above are the most commonly used. For more details, including information about lateral loading, please refer to the Silva Cell 2 Engineering Report and Testing Conclusions. For custom details and a review of your site-specific loading requirements, please This email address is being protected from spambots. You need JavaScript enabled to view it..

– 11,500 kg maximum per axle

– 5,750 kg maximum per wheel

– Tyre contact surface area is 200 x 200 mm

The table below provides the maximum load that can be on any single wheel (tyre), or per axle, for a given pavement section,

assuming tyres have a contact area equal to 200 mm x 200 mm as prescribed in the BS EN 1991-1-1:2002 including the UK annex,

category G (<160 kN gross vehicle weight, on 2 axles). For more details, including information about lateral loading, please refer to the

| Silva Cell System Type | Pavers | |

| 8 cm pavers 2.5 cm sand base 30 cm of aggregate |

||

| Wheel | Axle | |

| 1X | 121 kN | 242 kN |

| 12,338 kg | 24,676 kg | |

| 2X | 133 kN | 266 kN |

| 13,562 kg | 27,124 kg | |

| 3X | 113 kN | 226 kN |

| 11,523 kg | 23,046 kg | |

| Silva Cell System Type | Asphalt | |

| 10 cm of asphalt 30 cm of aggregate |

||

| Wheel | Axle | |

| 1X | 198 kN | 396 kN |

| 20,190 kg | 40,380 kg | |

| 2X | 218 kN | 436 kN |

| 22,229 kg | 44,458 kg | |

| 3X | 185 kN | 370 kN |

| 18,864 kg | 37,728 kg | |

| Silva Cell System Type | Concrete | |

| 10 cm of asphalt 10 cm of aggregate |

||

| Wheel | Axle | |

| 1X | 132 kN | 264 kN |

| 13,460 kg | 26,920 kg | |

| 2X | 145 kN | 290 kN |

| 14,786 kg | 29,572 kg | |

| 3X | 123 kN | 246 kN |

| 12,542 kg | 25,084 kg | |

| Silva Cell System Type | Pavers with Concrete | |

| 6 cm pavers 12.7 cm concrete |

||

| Wheel | Axle | |

| 1X | 150 kN | 300 kN |

| 15,296 kg | 10,592 kg | |

| 2X | 165 kN | 330 kN |

| 16,825 kg | 33,650 kg | |

| 3X | 140 kN | 280 kN |

| 14,276 kg | 28,552 kg | |

Loading capacity can be adjusted based on section profile changes; the typical applications shown in the table above are the most commonly used. For more details, including information about lateral loading, please refer to the Silva Cell 2 Engineering Report and Testing Conclusions. For custom details and a review of your site-specific loading requirements, please This email address is being protected from spambots. You need JavaScript enabled to view it..

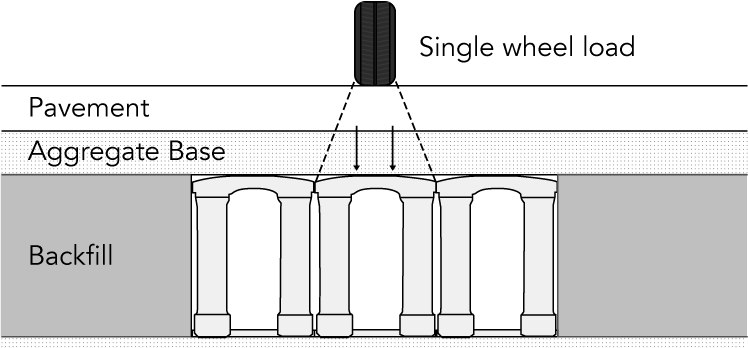

– 175 kN maximum per axle

– 87.5 kN maximum per wheel

– Tire contact surface area is 250 x 600 mm

The table below provides the maximum load that can be on any single wheel (tire), or per axle, for a given pavement section, assuming tires have a contact area equal to 250 mm x 600 mm. For more details, including information about lateral loading, please refer to the Silva Cell 2 Engineering Report and Testing Conclusions.

| Silva Cell System Type | Pavers | |

| 8 cm pavers 2.5 cm sand base 30 cm of aggregate |

||

| Wheel | Axle | |

| 1X | 147 kN | 294 kN |

| 33,100 lbs | 66,200 lbs | |

| 2X | 162 kN | 324 kN |

| 36,400 lbs | 72,800 lbs | |

| 3X | 137 kN | 274 kN |

| 30,900 lbs | 61,800 lbs | |

| Silva Cell System Type | Asphalt | |

| 10 cm of asphalt 30 cm of aggregate |

||

| Wheel | Axle | |

| 1X | 225 kN | 450 kN |

| 50,500 lbs | 101,000 lbs | |

| 2X | 247 kN | 494 kN |

| 55,500 lbs | 111,000 lbs | |

| 3X | 210 kN | 420 kN |

| 47,200 lbs | 94,400 lbs | |

| Silva Cell System Type | Concrete | |

| 10 cm of asphalt 10 cm of aggregate |

||

| Wheel | Axle | |

| 1X | 165 kN | 330 kN |

| 37,000 lbs | 74,000 lbs | |

| 2X | 181 kN | 362 kN |

| 40,700 lbs | 81,400 lbs | |

| 3X | 154 kN | 308 kN |

| 34,600 lbs | 69,200 lbs | |

| Silva Cell System Type | Pavers with Concrete | |

| 6 cm pavers 12.7 cm concrete |

||

| Wheel | Axle | |

| 1X | 184 kN | 368 kN |

| 41,400 lbs | 82,800 lbs | |

| 2X | 202 kN | 404 kN |

| 45,500 lbs | 91,000 lbs | |

| 3X | 172 kN | 344 kN |

| 38,700 lbs | 77,400 lbs | |

Loading capacity can be adjusted based on section profile changes; the typical applications shown in the table above are the most commonly used. For more details, including information about lateral loading, please refer to the Silva Cell 2 Engineering Report and Testing Conclusions. For custom details and a review of your site-specific loading requirements, please contact DeepRoot.