We are well into the fifth year of providing reviews for Silva Cell layouts and details for projects around the world. In that time, we have seen drawings from early concept development level to ready-to-go-in-the-ground, and the Silva Cell system certainly runs the gamut for level of completion in those drawings.

We are well into the fifth year of providing reviews for Silva Cell layouts and details for projects around the world. In that time, we have seen drawings from early concept development level to ready-to-go-in-the-ground, and the Silva Cell system certainly runs the gamut for level of completion in those drawings.

There are a handful of issues that come up frequently in our plan reviews, things that are easy to correct earlier in the process so that your project bids can be more accurate and installation can go more smoothly.

The TOP 5 most common technical issues with Silva Cell layouts and details are:

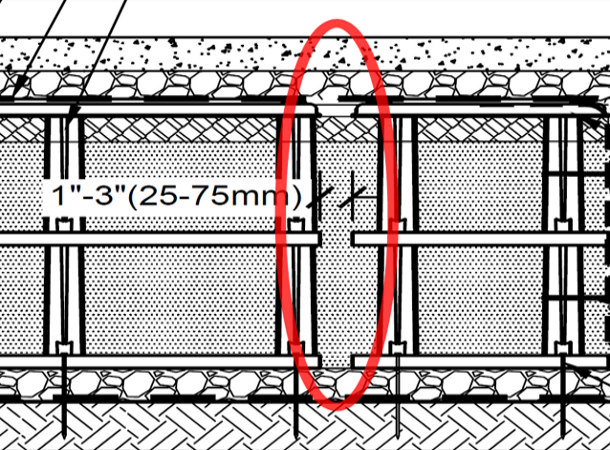

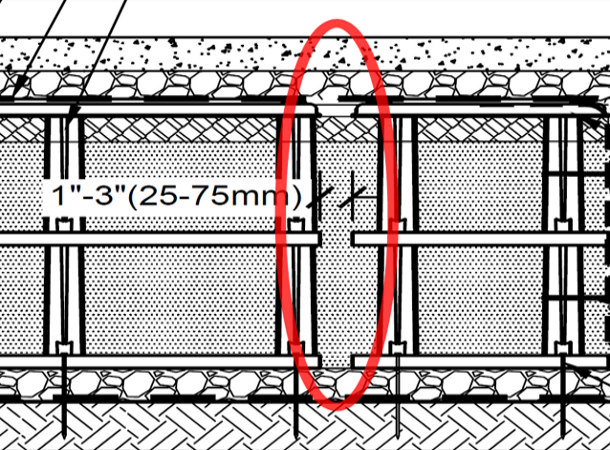

5. Inadequate spacing between the Cells.

Silva Cells are modular units that stack in columns. Each column is freestanding and is not connected to adjacent columns. A 1” (25mm) to 3” (75mm) space between each Cell (if a one layer system) or column (if a multilayer system) is required. You do not need to use the same spacing across the whole site – as long as it’s 1″ – 3″, you’ll be fine. The modularity and this varied spacing allows the Cells to fit easily on most sites.

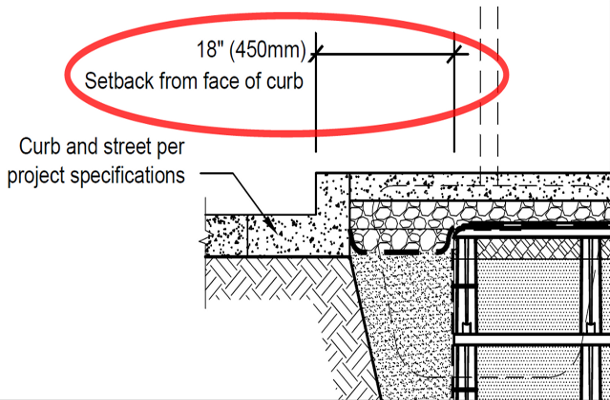

4. Incorrect curb setbacks.

When using Silva Cells adjacent to a roadway, we maintain an 18” (450mm) setback from the face of the curb. This has been engineered based on the angle of repose for loads applied at the curb. The face of curb is often easy to offset in CAD to make sure you start your Cell layout from this setback, rather than directly behind the curb.

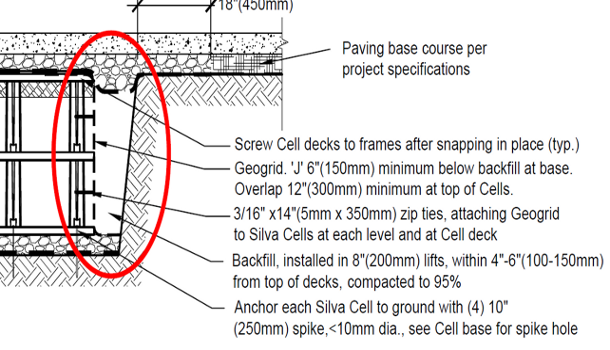

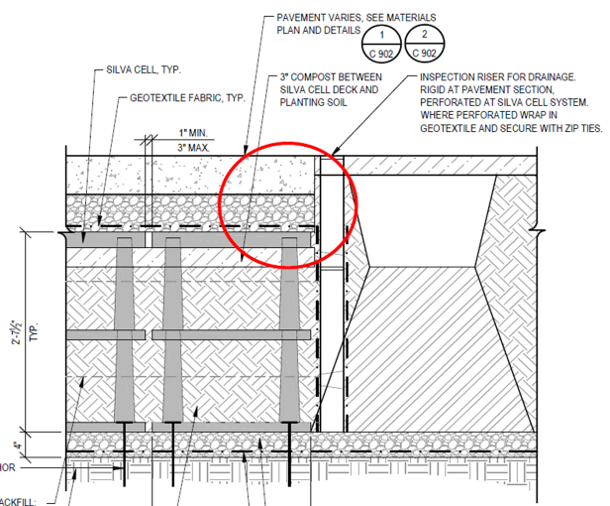

3. Details don’t include the backfill zone.

The outside of the Silva Cell system is wrapped in a geogrid which is critical to good backfill compaction against the Cells. Many designers omit this portion of the details, which are important for accurate bidding and CRITICAL to construction of the system.

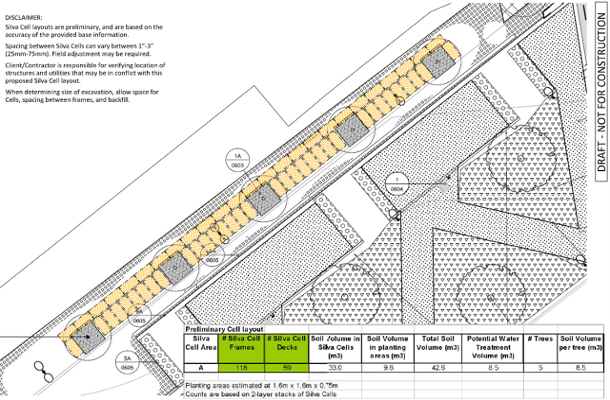

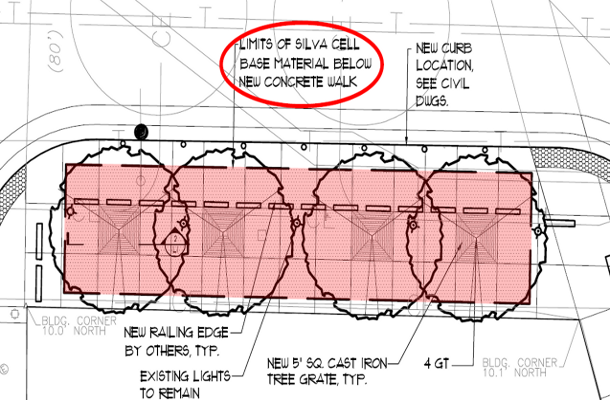

2. Estimating based on a Silva Cell “zone” without an actual layout.

While the Silva Cell system is modular and can work for virtually every site, it is not advisable to move into Construction Documents without an actual Cell layout. We see lots of drawings with Silva Cell “zones” noted or calculations based on the square footage of the specific area. Due to Cell spacing, curb setbacks, and how the Cells can actually fit between tree openings, this is not a great way to quantify Cells for your site. We provide Cell layout services that will be more precise for quoting and ultimately for construction.

1. Lack of support at the tree opening. This is #1 for good reason, it has many facets.

- The primary issue we see is the lack of a “curb” coming down to the Cell decks at the tree opening. As loads are applied, the aggregate base course will shift, slowly migrating into the tree openings because nothing is holding it back.

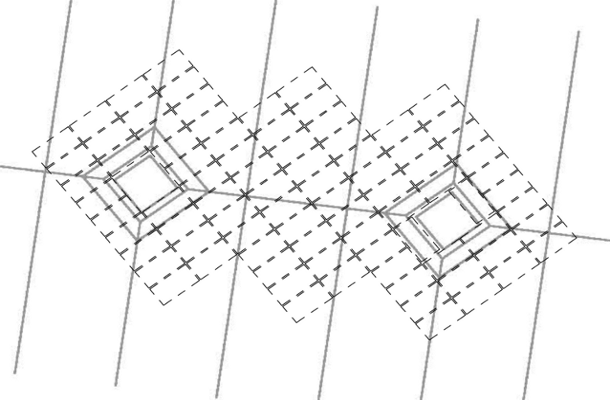

- Diamond shaped and circular tree openings can be tricky. We want to provide continuous support, but not to have the Cells extend too far into the planting area.

- We often see planters with a thick concrete edge, but the Cells are shown just outside this zone. What is supporting that concrete? Shift the Cells in to the edge of the tree opening, aligning the Cell posts as the primary support.

DeepRoot provides customer support at every stage of your project. Please contact us if you have questions along the way.

Reason 1: would it not be a good idea to start provding a fixed and ready treeopening which meets our standards and sizes?

I am willing to make an investigation on that, i can deliver ready concrete made tree openings for the treepit. Let me know what you want and which sizes and i ‘ll go after it. regards Eric

How can the Silva Cell system best accommodate a circular tree opening such as a 48″ dia round opening in pervious brick paver surface. Would like a circular collar around the tree opening?